|

Kingwell Fibre Materials Co., Ltd

|

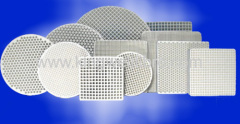

silica mesh casting filter

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

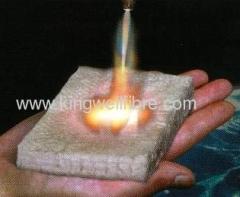

Silica Mesh Casting Filter is particularly effective at extracting dross, slag, refractory particles and nonmetallic inclusions.

Filtering with Silica Mesh Casting Filter is an effective way to remove inclusions and slag from steel, copper-based metal alloys, aluminium, gray, malleable, white, compacted graphite and ductile cast iron. Able to withstand pouring temperatures up to 1650C.deg (3000F), filter shapes help trap inclusions and reduce turbulence during the casting process. On contact with molten metal, the surface fibers of the filter form a sticky layer of fayalite. This allows the mesh filter to remove even micron-sized inclusions from the beginning of the pour to the end.

Silica Mesh Filtration is an economical solution at extracting dross,slag, refractory particles and nonmetallic inclusions,make the waste product of casting reduce by 50~60%.

Features:

In metal filtration,Silica Mesh Filters offer following unique advantages that ceramic foam and cellular filters do not:

*Best Results with Hot Topping – the filter can easily be removed after the pour so that there is no metal flow restriction during the exothermic action of the Hot Topping.

*No custom pour cone required – foundries using ceramic foam or cellular filters typically have to use custom-made pour cones that have a small ledge added to the inner wall of the bottom for the filter to sit on.

*Can sit on the top of any standard pour cone.

*No pre-heat required –unlike ceramic foam or cellular filters, silica mesh filters can be placed in the pouring cone just prior to the pour.

Specifications:

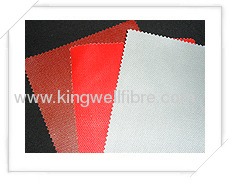

Standard Mesh Sizes:1.5×1.5, 2.0×2.0,2.5×2.5mm

Various flat sheets, pressed shapes are customized to order.

P.S: Our maximum sheet size is:900×1,050mm

Usage Method:

The filter of necessary size is cut and installed into the gating system or directly under the pouring gate between the bottom and top moulding boxes of a mould.

Remarks:The cut silica mesh sizes should be 20~30mm larger than the material pouring gate.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!