|

Kingwell Fibre Materials Co., Ltd

|

Fiberglass needled mat/ Needled glass felt

| Payment Terms: | T/T |

| Place of Origin: | , China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Fiberglass needled mat/ Needled glass felt/ Fiber glass needled felt

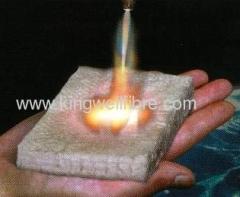

Fiberglass needled mat/ Needled glass felt is an advanced material for thermal insulation and air cleaning made by cutting continuous E-glass fibers into given length and then felting them through a process of filamentizing, napping and needling.

100% fiberglass material,without adhesive,Characterized by high temperature resistance, good thermal insulation, superior acoustic absorptivity and high efficiency of cleaning tail gas.

It has found wide application in mechanical, electrical, chemical, metallurgical, petroleum, coal, building and traffic industries, suitable for the use as sandwiched heat and sound insulation system in automobile, ship, and train carriages. When treated with a ternary rare-earth cleaning catalyst, it is an ideal material for tail gas cleaning and sound deadening for cars and motorcycles.

Specifications:

Thickness | 3-25mm |

Density | 100 -200 kg/m3 |

Width | 500-2400mm |

Temperature resistance | 700℃ (shrinkage at 650℃) |

Thermal conductivity | 0.058 W/m.k (Average Value at 300℃) |

Moisture absorptivity | <5% |

Applications:

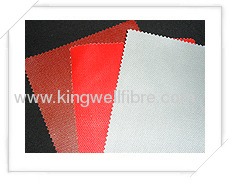

--Subsequent to being dipped into the resin and next processed into lath shapes, the glassfibre blanket is applicable to building construction and gaskets of air conditioners for heat insulation and noise elimination.

--Subsequent to the laminating for aluminum foil and PVC fabrics on the surface and next being processed into straps, it is provided for thermal insulation and protection of cold/hot piping and underground pipes.

--Employed as heat-resistant, tensile, waterproof, anti-erosion materials including heatproofing of engine hoods, cars mufflers, thermal insulation materials of industrial boilersand being able to replace expensive fully-importing asbestos goods.

Related Search

Fiberglass Needled Mat

Fiberglass Mat

Fiberglass Needle Felt

Glass Wool Felt

Fiberglass Needle Mat

Fiberglass Chopped Mat

More>>